15- Cladding Design as Shear Diaphragm

A purlin is a secondary structural member in a roof system that spans between the primary frames or rafters. Its main function is to support the roof covering (such as metal sheeting or panels) and transfer the loads—such as dead load, wind, and snow—to the main structural system of the building.

The design of purlins is one of the most critical aspects of Pre-Engineered Building (PEB) design. Although purlins are classified as secondary framing members, they directly influence the strength, stability, and economy of the roof system.

Inadequate or overly conservative design can either compromise safety or increase project cost unnecessarily. Therefore, an optimized methodology for purlin design is essential for achieving both performance and economy in modern PEB structures.

Purlin Design Methodologies

Method 1:

In an approach for purlin design, presented in the “Roof Framing Design Guide for Metal Building Systems, 2nd Edition”, purlins are required to have sufficient strength to resist both gravity loads and uplift loads.

The design checks are performed according to the AISI S100 Specification, and include:

- Bending Strength (AISI S100, Chapter F)

- Shear Strength (AISI S100, Section G2.1)

- Combined Bending and Shear (AISI S100, Section H2)

- Web Crippling Strength (AISI S100, Section G5)

- Combined Bending and Web Crippling (AISI S100, Section H3)

Moreover, in this reference, the term “Strut purlin” is introduced to describe purlins that are specifically responsible for resisting wind-induced forces. Unlike regular purlins, these members are subjected to significant axial forces in addition to bending. Accordingly, the following design checks are required:

- Axial Load Strength

- Combined Compressive Axial Load and Bending Strength (AISI S100, Section H1.2)

Method 2:

Another approach, recommended in the “European Recommendations for the Application of Metal Sheeting Acting as a Diaphragm – Stressed Skin Design”, considers the roof sheeting itself as a shear diaphragm which provides a stabilizing action (to prevent flexural, flexural-torsional and flexural-lateral buckling or a combination of these).

In this method, the sheeting provides both stiffness and strength, thereby stabilizing secondary members such as purlins. Under this methodology, purlins are not designed to carry axial loads. Instead, the sheeting is designed and verified to provide the required stabilization, and purlins are designed to resist just bending and shear.

Analytical and Experimental Studies

The stabilizing effect of cladding on primary and secondary structural elements has been investigated in several studies. Below some of the research are presented.

Research 1:

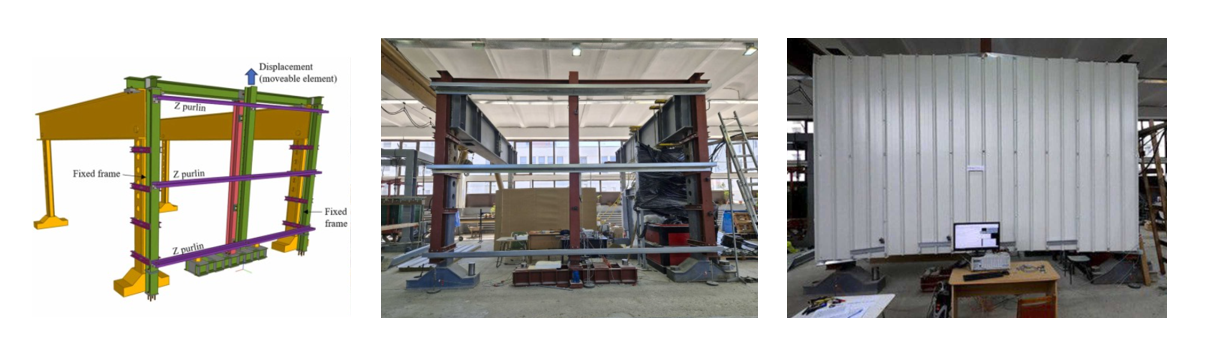

In research by Židlický et al. in 2024, an experimental study about the influence of sandwich panel cladding on horizontal stiffness of a steel monopitch portal frame structure made in two stages – without and with roof sandwich panel cladding. The results from the reference, are presented in figure below.

References: Židlický, B., Mareš, J. and Wald, F., 2024. The influence of sandwich panel cladding on horizontal structure stiffness. Thin-Walled Structures, 199, p.111771. https://doi.org/10.1016/j.tws.2024.111771

Research 2:

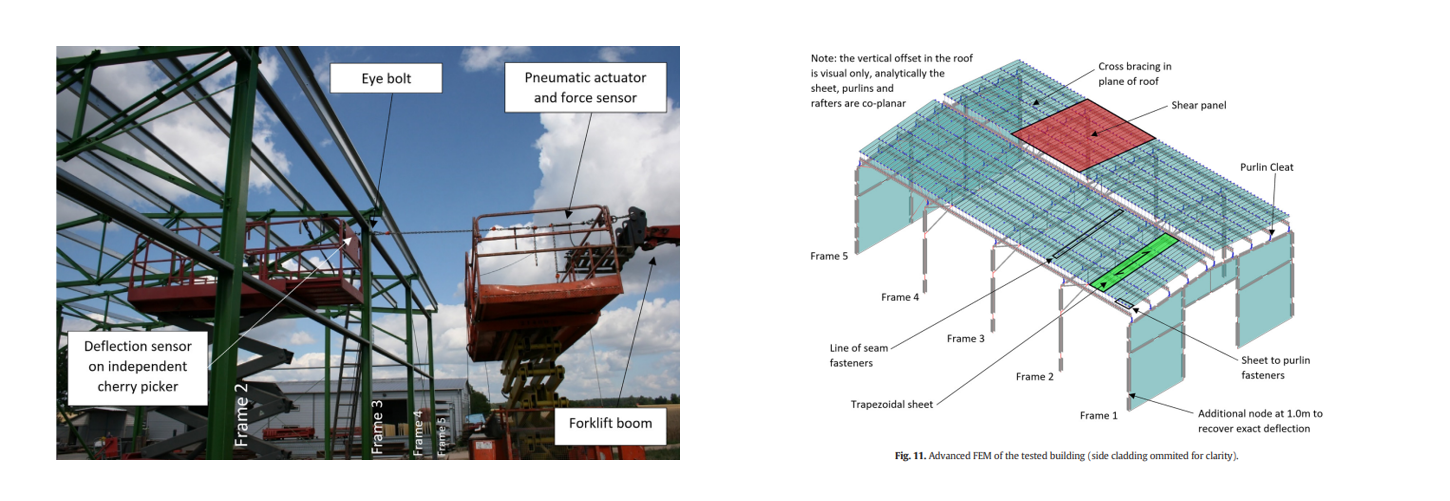

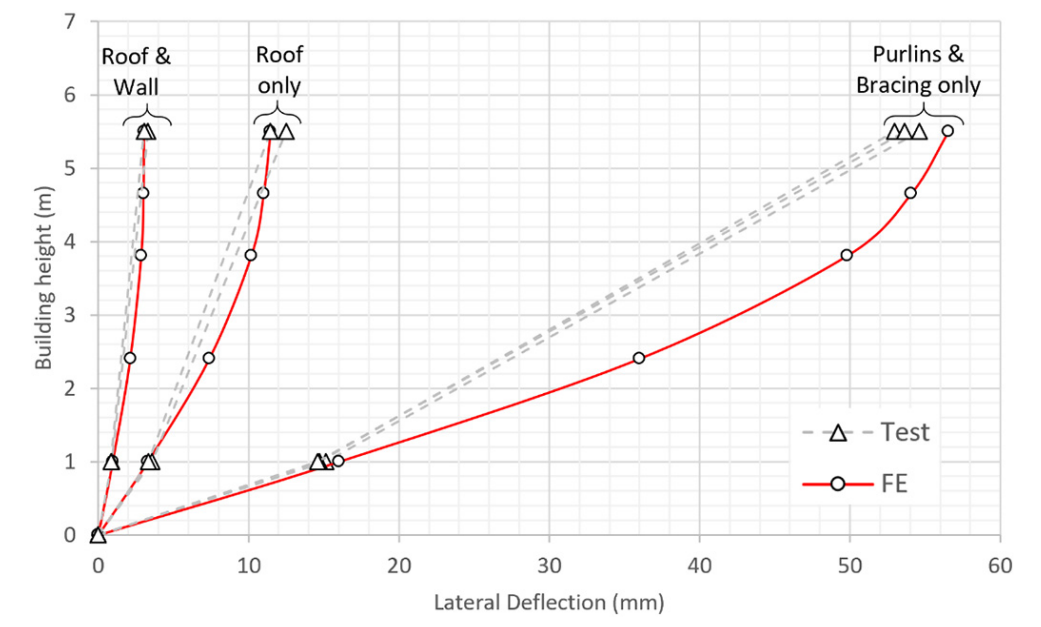

In another research on a full-scale steel-framed building, the influence of structure-cladding interaction is investigated. The experimental and analytical studies are carried out in 3 phases, 1:no cladding, 2: roof cladding only, and 3 roof and walls clad.

Below you can see the comparison of test results and FE, of column deflection at frame 3 with a 10kN load at frame 3.

Reference: Gryniewicz, M., Roberts, M.J. and Davies, J.M., 2021. Testing and analysis of a full-scale steel-framed building including the consideration of structure-cladding interaction. Journal of Constructional Steel Research, 181, p.106611. https://doi.org/10.1016/j.jcsr.2021.106611

Research 3:

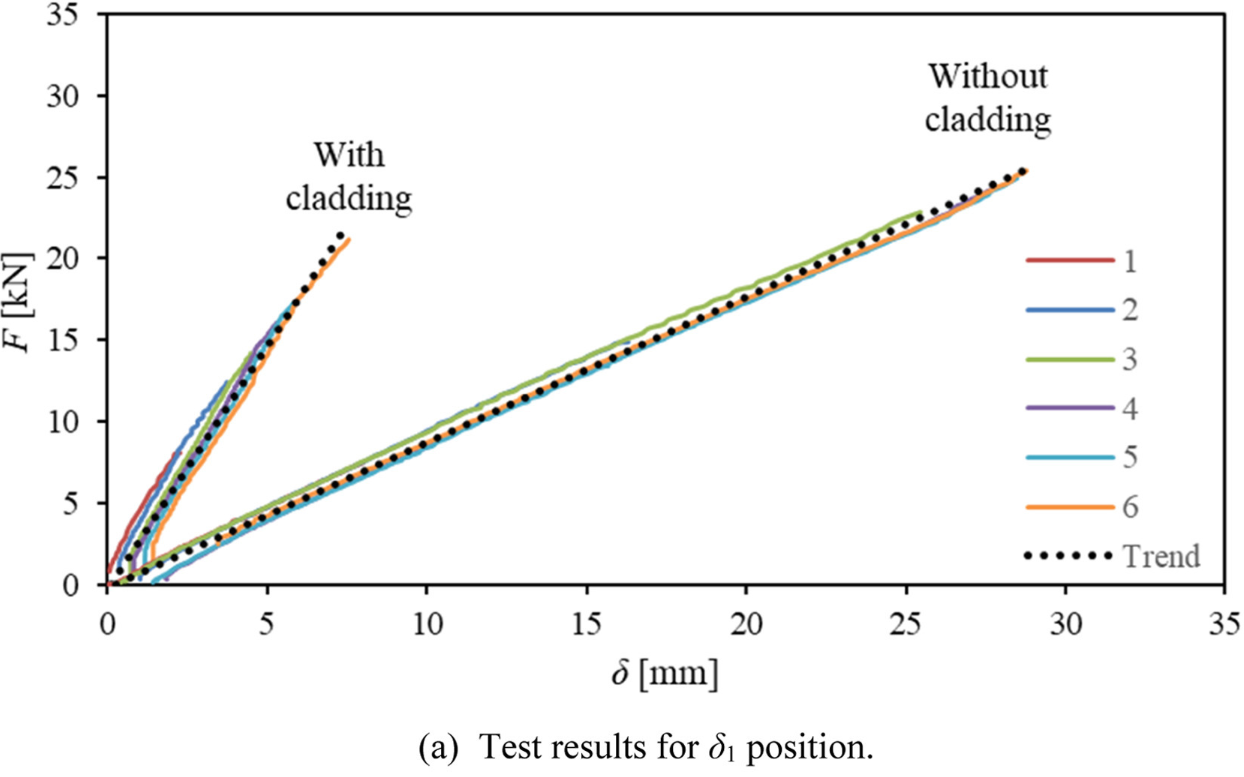

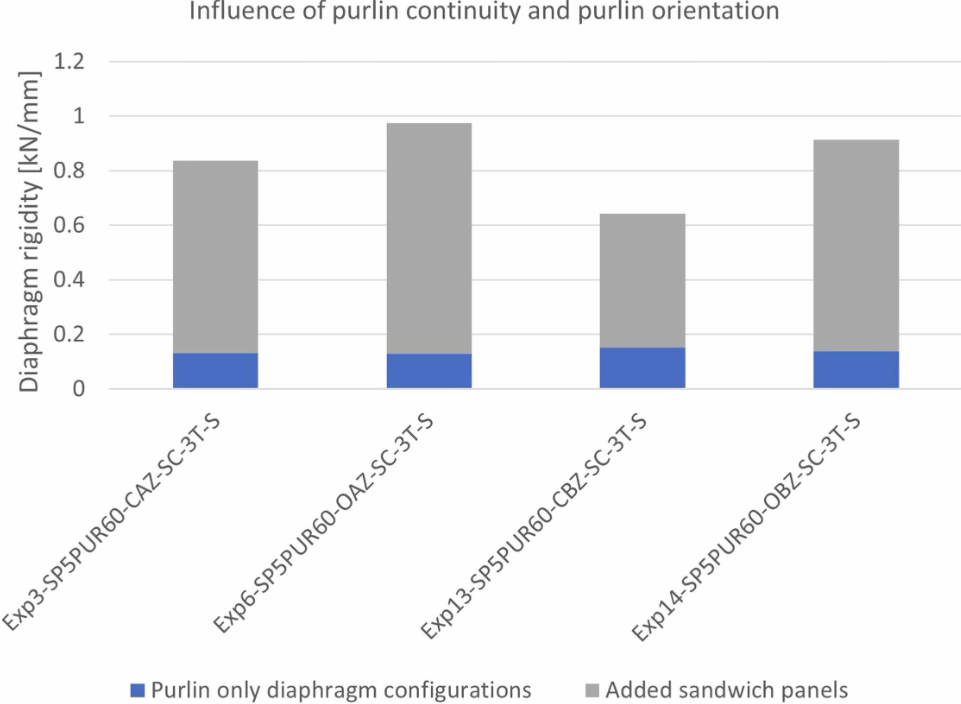

In another research, diaphragm rigidity of purlin only diaphragm configurations and the supplemental diaphragm rigidity due to the inclusion of the cladding is investigated.

Below you can see the effect of the adding sandwich panels in the diaphragm rigidity.

Reference: Kelemen, A.R., Nagy, Z. and Lőrincz, B.A., 2025. Experimental testing of stressed skin effect of sandwich panel roof diaphragms–Test result evaluation considering diaphragm rigidity. In Structures (Vol. 80, p. 110073). Elsevier. https://doi.org/10.1016/j.istruc.2025.110073

Other research

More research paper on this topic can be found through the links below:

https://doi.org/10.1016/j.tws.2021.108415

https://doi.org/10.1016/j.tws.2022.109264

https://doi.org/10.1016/j.istruc.2021.06.098

https://doi.org/10.1016/j.istruc.2023.105064

Implemented Methodology:

MkaPEB, as a leading software for Pre-Engineered Building (PEB) design, enables engineers to achieve the most cost-effective solutions by designing roof and wall sheeting to function as an effective shear diaphragm, fully compliant with applicable standards. This strategy not only reduces the weight and cost of secondary members, such as purlins and girts, but also helps minimize repair and maintenance costs after severe wind or seismic events, because using the cladding as a shear diaphragm ensures that damage from extreme loads is mostly limited to the cladding, which is much easier, cheaper, and faster to replace than damaged purlins or other structural members.

The methodology used in MkaPEB is to design cladding (Metal Sheeting and Sandwich Panel) to function as a stabilizing element is presented below.

Determination of strength and stiffness of a METAL SHEETING acting as a stabilizing element

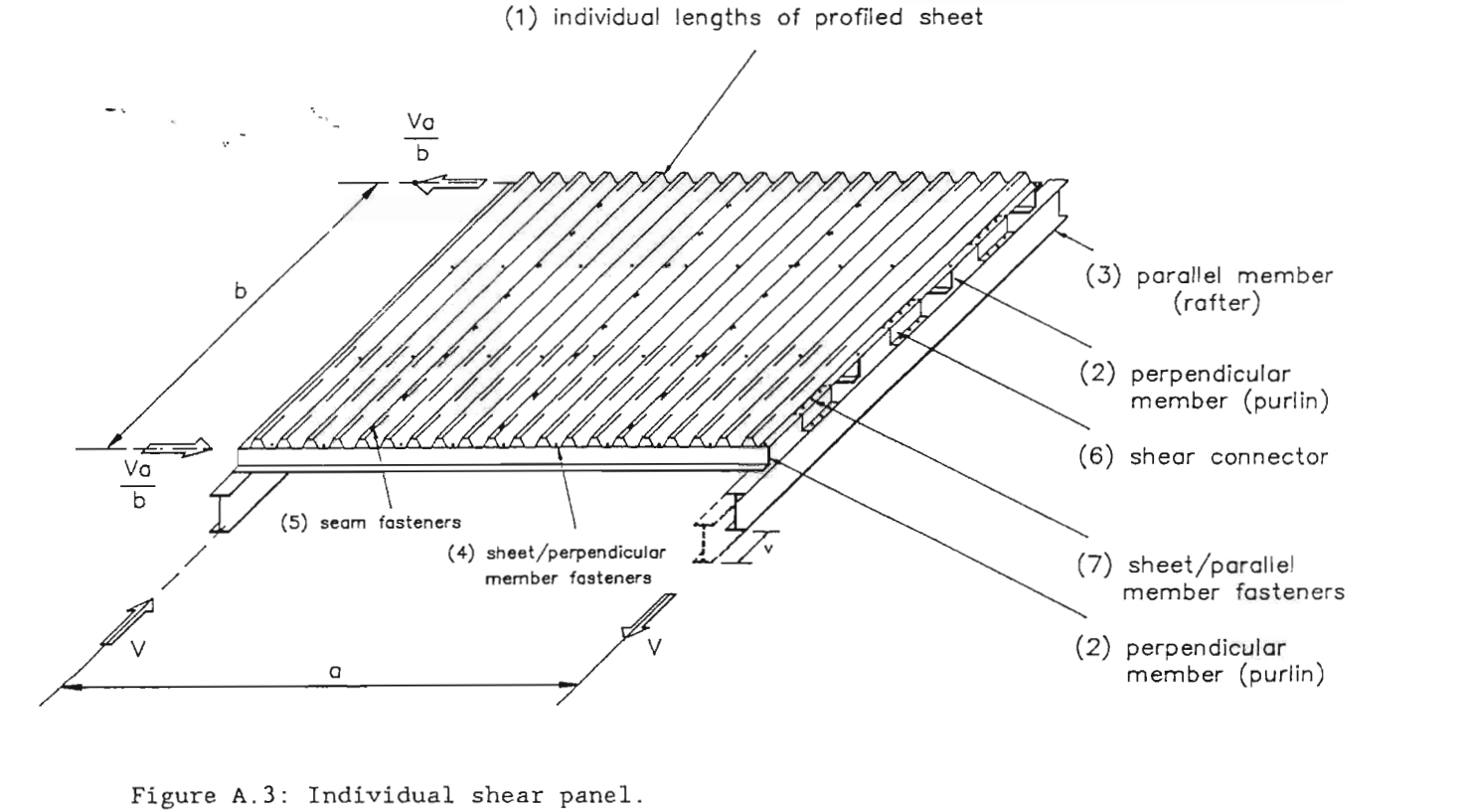

When a metal sheeting has been used as a stabilizing element (to prevent flexural, flexural-torsional and flexural-lateral buckling or a combination of these) the stiffness perpendicular to the section, which has to be stabilized, should be known. From the assumed calculation model the following can be determined:

a) the shear stiffness of the shear panel,

b) the shear strength of the shear panel.

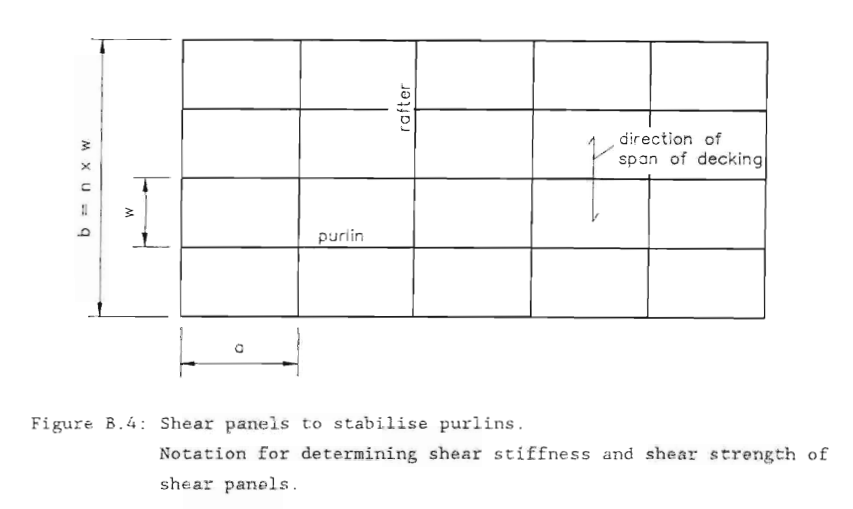

Shear stiffness and shear strength of a metal sheeting on purlins.

a) Shear stiffness of the metal sheeting to stabilize purlins

b) Shear strength of the metal sheeting to stabilize purlins

Reference: ECCS, T., 1995. European recommendations for the application of metal sheeting acting as a diaphragm: stressed skin design. In European convention for constructional steelwork.

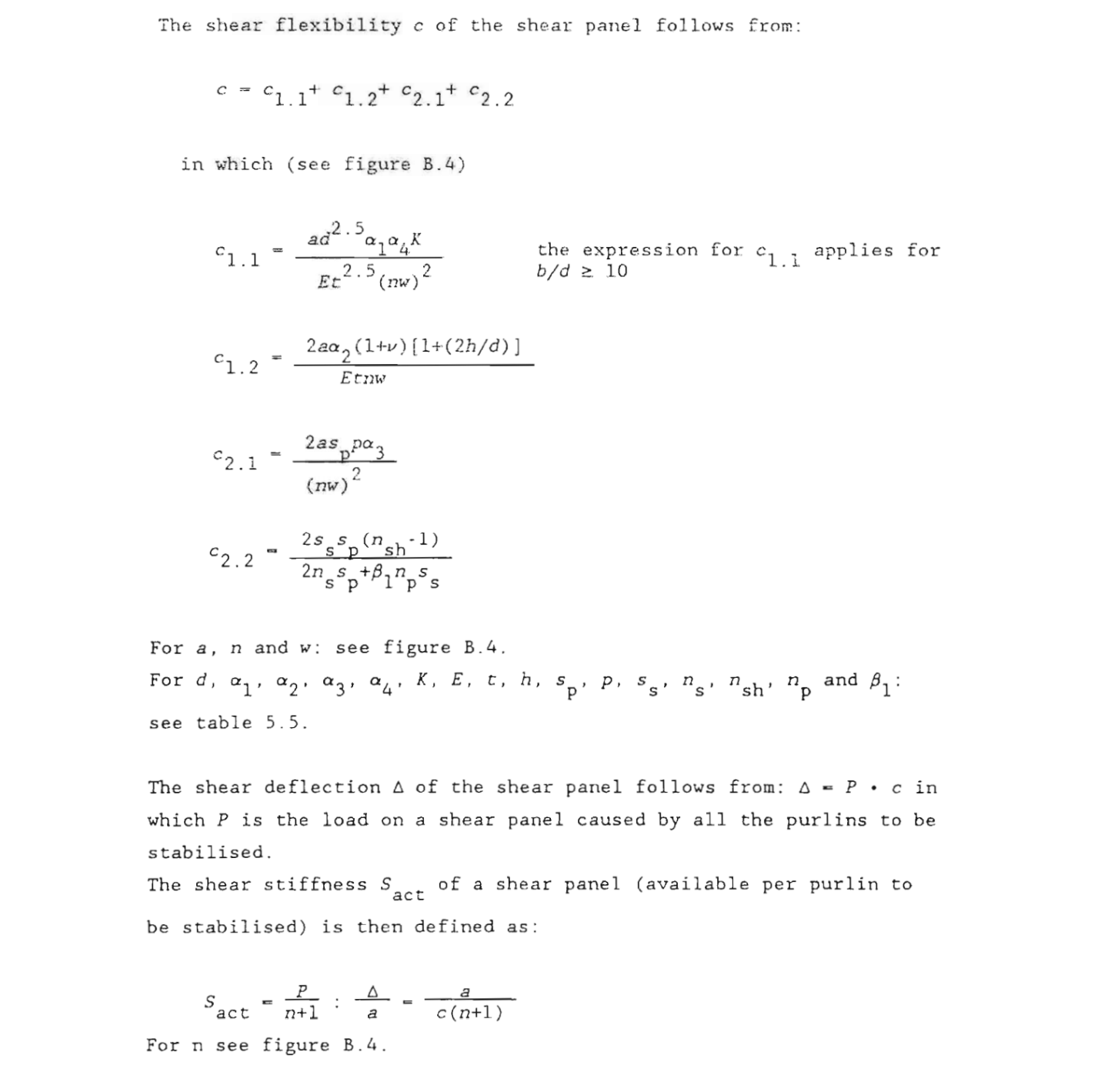

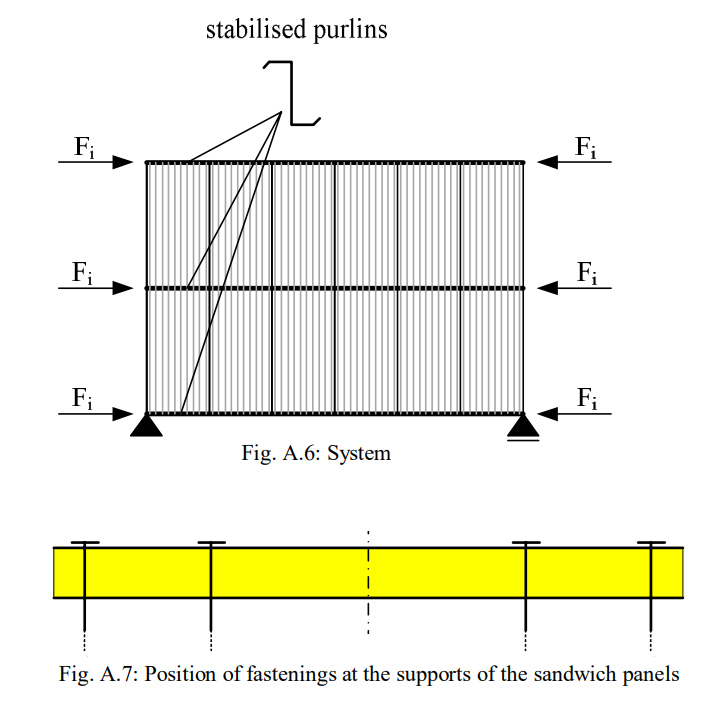

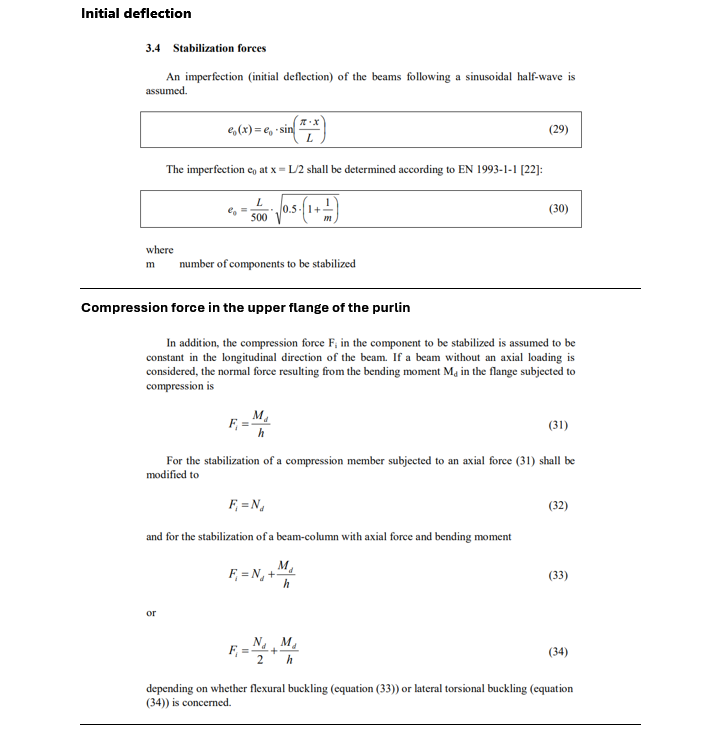

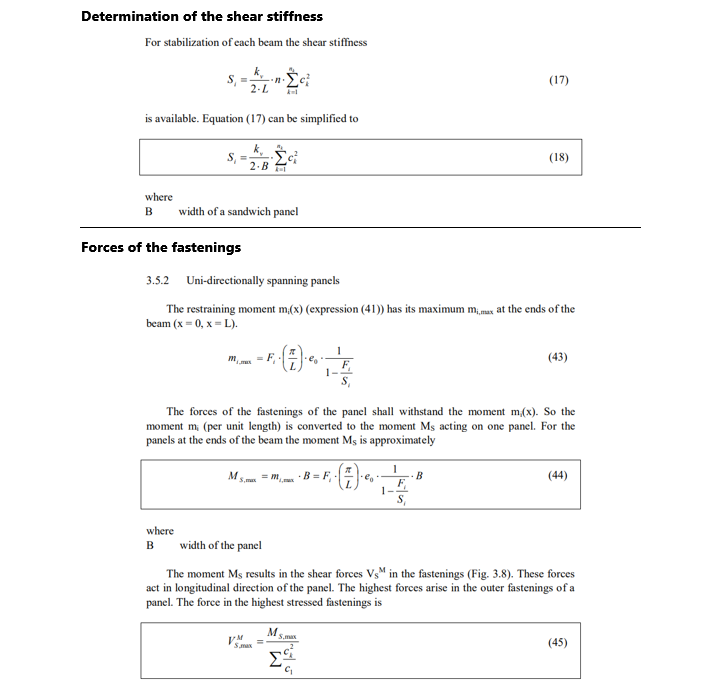

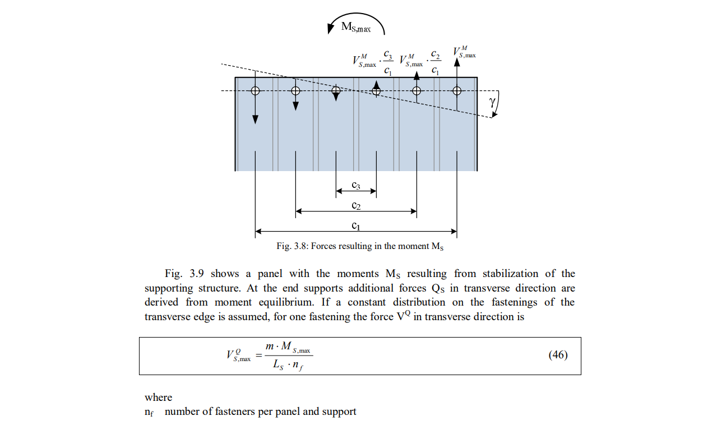

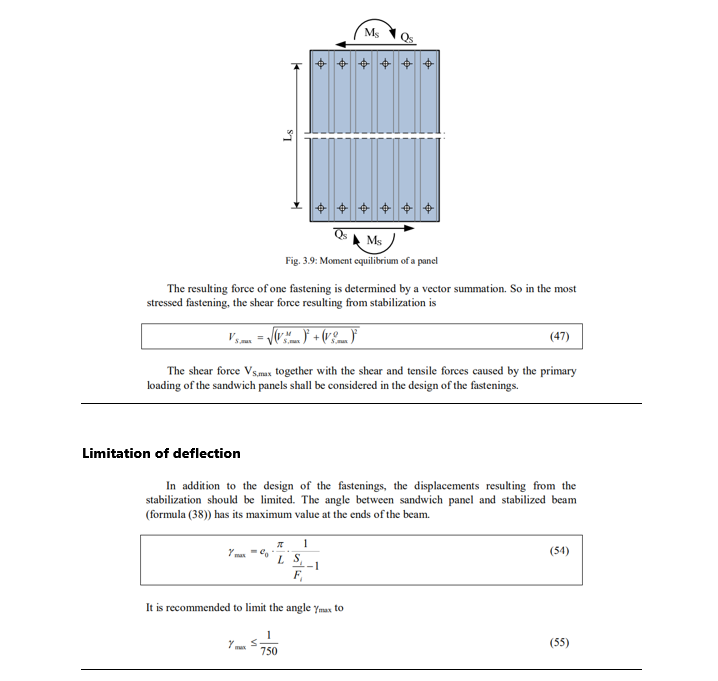

Determination of strength and stiffness of a SANDWICH PANEL acting as a stabilizing element

Reference: ECCS, T., 2014. European Recommendations on the Stabilization of Steel Structures by Sandwich Panels. In European convention for constructional steelwork.