9- Expansion Gaps

In structural engineering, thermal expansion is often underestimated or oversimplified—leading to over-restrictive designs or long-term structural stress accumulation. At MkaPEB, we go beyond the conventional approach. Our design logic comprehensively factors in the thermal behavior of structures to achieve optimized, and safer solutions.

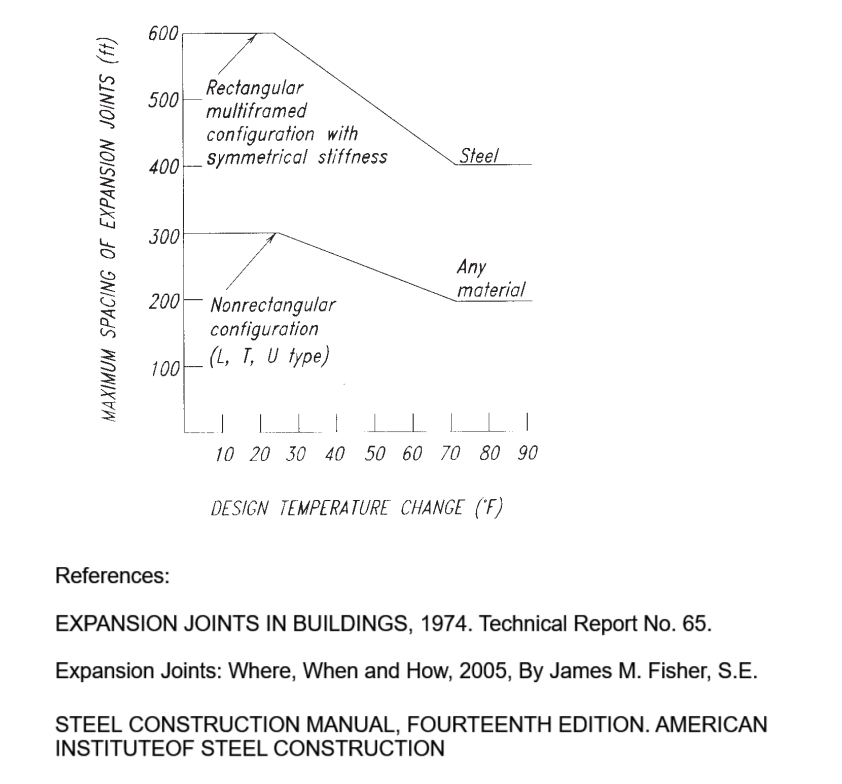

Due to temperature changes, structural members expand or contract, which can introduce significant internal stresses if not properly accounted for. To address this, expansion joints are introduced when a structure’s horizontal dimensions exceed certain limits. The Maximum allowable building length without expansion joints is dependent upon many variables, including ambient temperature during construction and the expected temperature range during the lifetime of the building.

https://vulcraft.com/files/DesignTools/ExpansionJointsinBuildings-NAS-FCCTechReport65.pdf (PDF Page: 14/53)

https://www.aisc.org/globalassets/modern-steel/archives/2005/04/2005v04_expansion_joints.pdf (PDF Page: 2/4)

https://www.16streets.com/39-B/PDF%20files/AISC_Steel_construction_manual_fourteenth_edi.pdf (PDF Page: 178/2325)

While many designs stop at simplified assumptions, our software goes several steps further. MkaPEB dynamically adjusts allowable spans based on a matrix of practical real-world conditions:

1. If the building will be heated only and will have pinned column bases, use the maximum spacing as specified.\

2. If the building will be air-conditioned as well as heated, increase the maximum spacing by 15% provided the environmental control system will run continuously.

3. If the building will be unheated, decrease the maximum spacing by 33%.

4. If the building will have fixed column bases, decrease the maximum spacing by 15%.

5. If the building will have substantially greater stiffness against lateral displacement in one of the plan dimensions, decrease the maximum spacing by 25%.

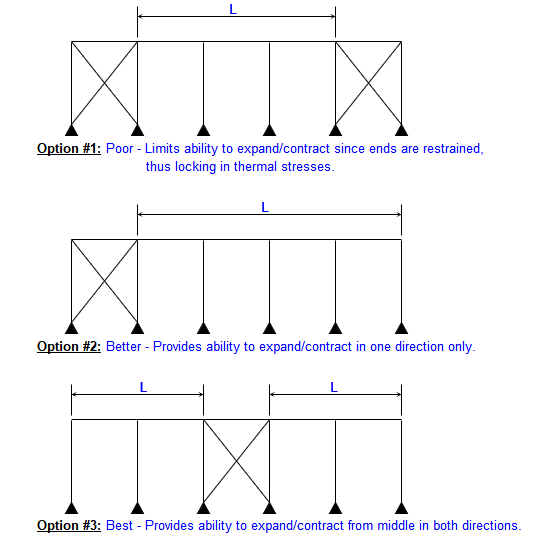

Moreover, the influence of inter-frame bracing configuration is specifically considered. As shown below, bracing layout directly affects how a building can expand or contract. While conventional systems may restrict movement and lock in thermal stresses (Option 1), MkaPEB promotes bracing strategies like Option 3, which allow balanced expansion from the center, minimizing structural stress buildup over time.

Such attention to detail sets our design approach apart—ensuring our solutions are not only code-compliant but also materially efficient, long-lasting, and structurally sound.

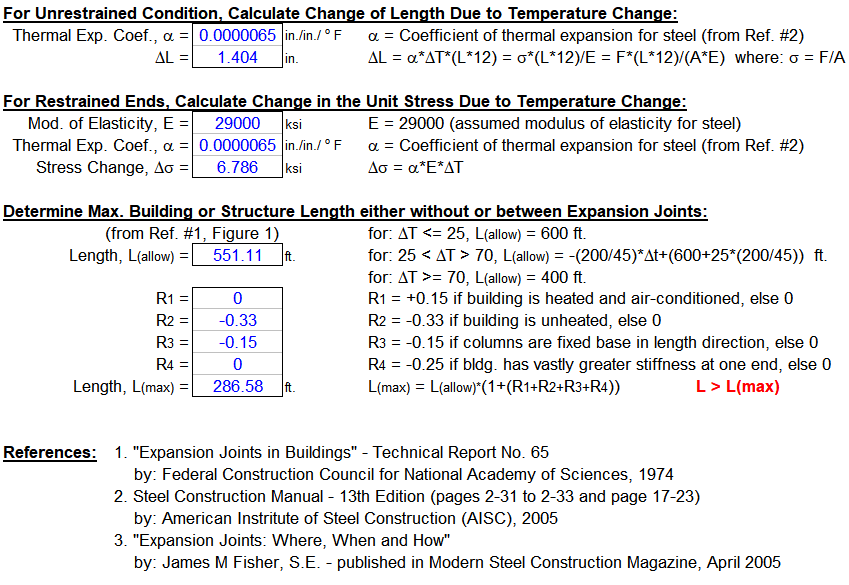

Considering all the above-mentioned factors MkaPEB calculates the maximum spacing of the expansion joints:

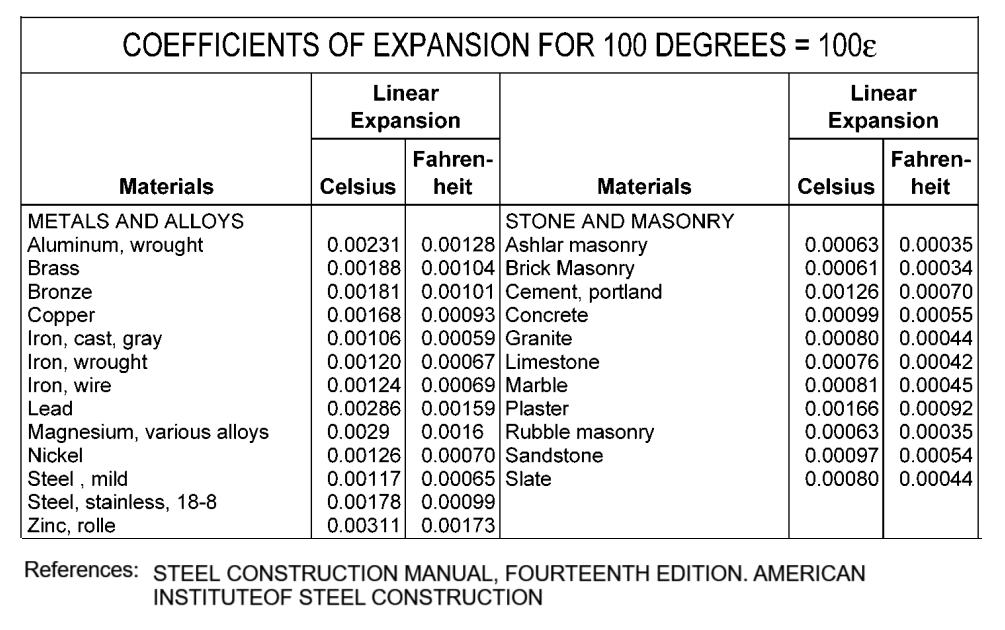

To support the calculations, MkaPEB uses coefficient data from authoritative sources, as shown in the material-specific table below.

https://www.16streets.com/39-B/PDF%20files/AISC_Steel_construction_manual_fourteenth_edi.pdf (PDF Page: 2276/2325)