Pre-engineered building

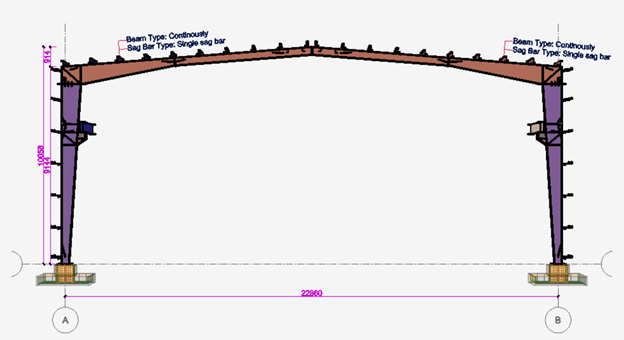

Example 1: Pre-engineered building

Problem:

To verify the reliability and code compliance of the structural model produced by MkaPEB, a comparative analysis was conducted between MkaPEB and SAP2000. The comparison focused on key response parameters, including support reactions, eave node displacements, and element capacity ratios of the PEB system. For this purpose, the structural model and loading defined in MkaPEB were exported to SAP2000, where the analysis and design was performed under the same conditions.

Results:

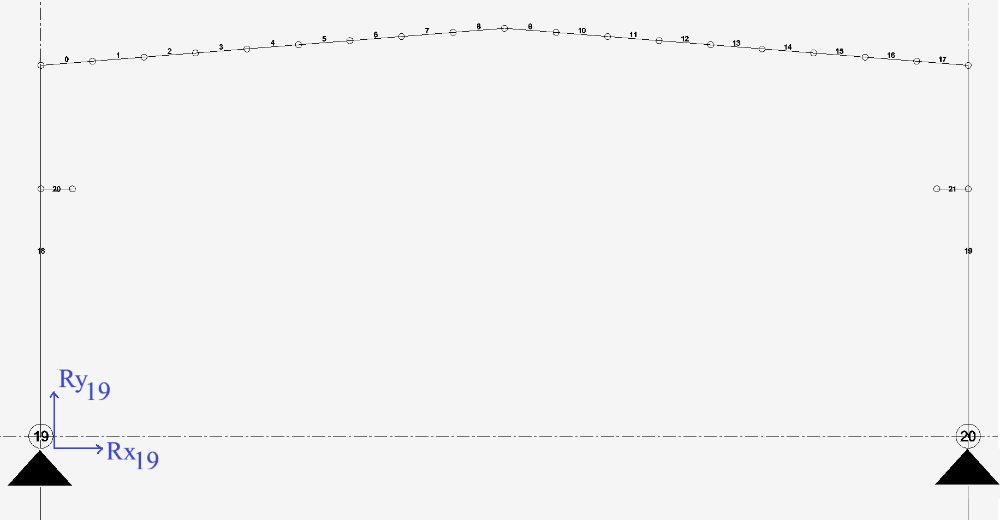

Support Reactions Verification

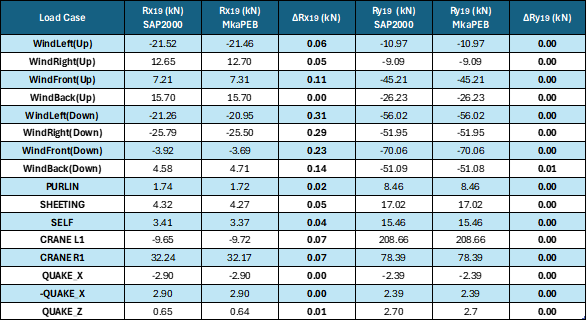

In this section, the joint reactions at the left column support (Rx19 and Ry19), illustrated in the figure below, are analyzed using both MkaPEB and SAP2000. The results are summarized in Table 1.

Table 1 Support Reactions - Comparison and Verification

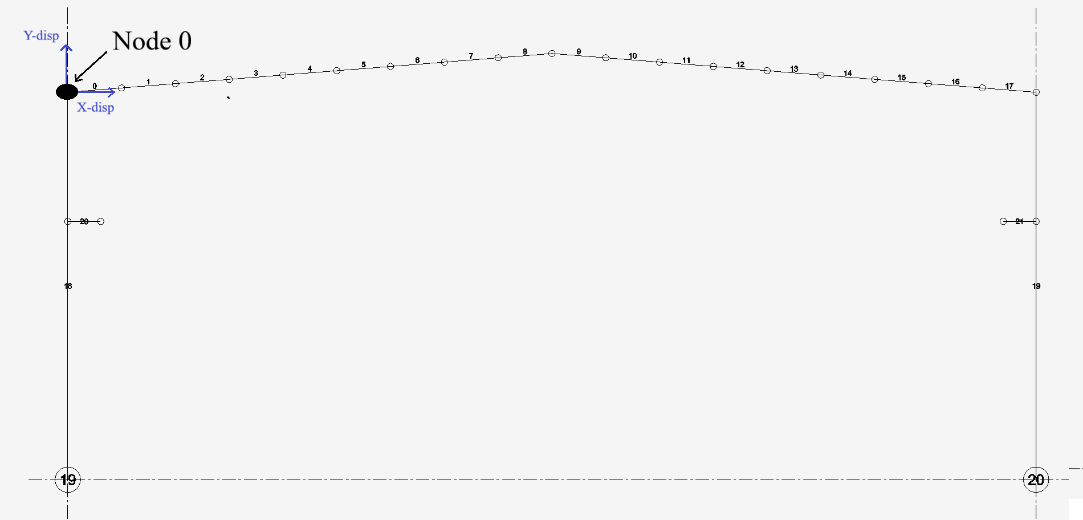

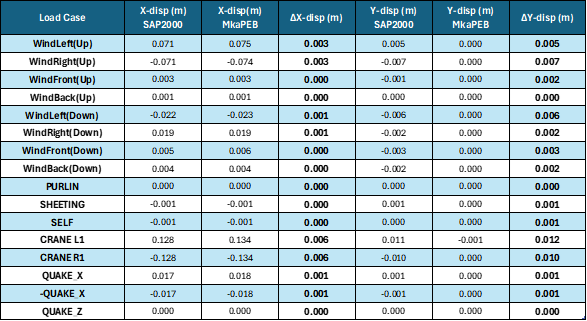

Joint Displacements Verification

In this section, the joint displacements at the left column eave (X-disp and Y-disp of Node 0), illustrated in the figure below, are analyzed using both MkaPEB and SAP2000. The results are summarized in Table 2.

Table 2 Joint Displacements - Comparison and Verification

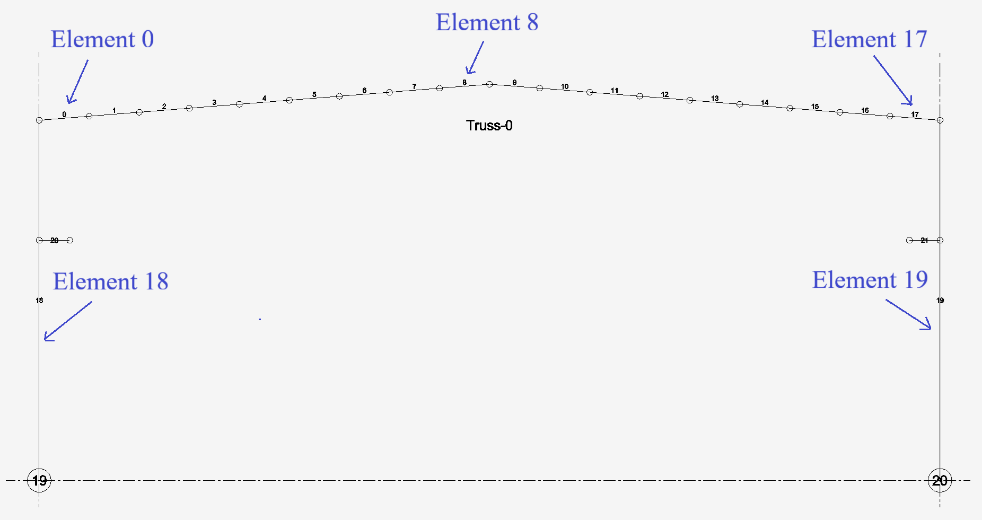

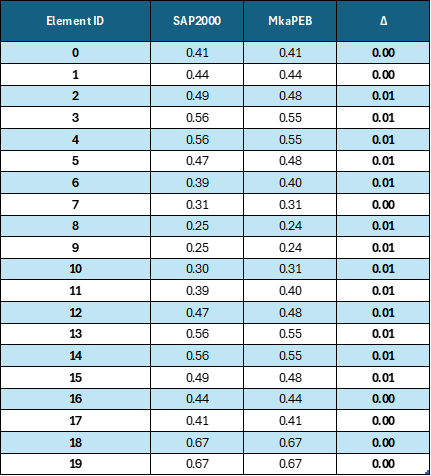

Capacity Ratios Verification

In this section, the capacity ratios of the structural elements, illustrated in the figure below, are analyzed using both MKAPEB and SAP2000. The results are summarized in Table 3.

Table 3 Element Capacity Ratios – Comparison and Verification

Conclusion:

The comparison demonstrates that the differences between MkaPEB and SAP2000 are negligible, both in terms of structural analysis outputs (support reactions and displacements) and design results (element capacity ratios). This confirms the consistency and reliability of the MkaPEB platform.