Design of Beam Lateral Bracing

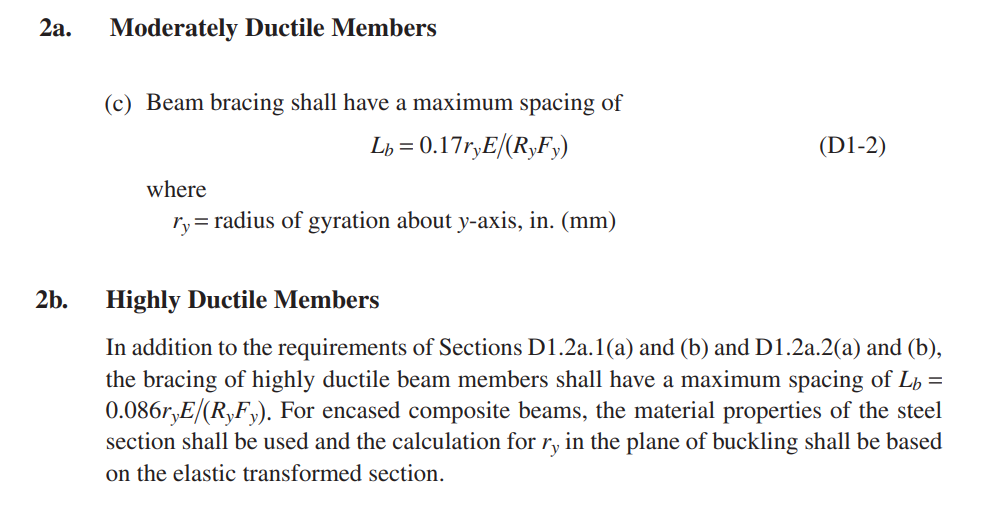

Unbraced length of beams are limited by codes and standards. In, AISC341-22 (CHAPTER D - Section 2a, 2b).

https://www.aisc.org/globalassets/aisc/publications/standards/a341-22w.pdf

To satisfy this limitation, either a higher size beams or bracing systems such as tie beams and flange bracing are needed.

Although, a few engineers prefer the first solution (using higher size beams), the other engineers use different bracing systems such as tie beams, flange bracing.

Flange (Fly, Diagonal) braces are commonly employed from the purlins to the inside flanges of the primary frames at various locations where the inside flange of the members needs to be restrained out-of-plane.

However, this type of bracing, which is significantly more economical than other bracing methods in portal frame, and pre-engineering building systems, should be designed based on brace requirements from the ANSI/AISC 360-16 (2016) Appendix 6:

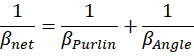

where

βPurlin is the stiffness of purlin

βAngel is the stiffness of flange brace

Ref: AISC video available on: https://www.aisc.org/education/continuingeducation/education-archives/applications-of-aisc-appendix-6-bracing-concepts-n11a/) , Time: 55:00 - 62:00)

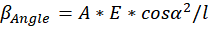

In the above equation βAngle is calculated by the following equation:

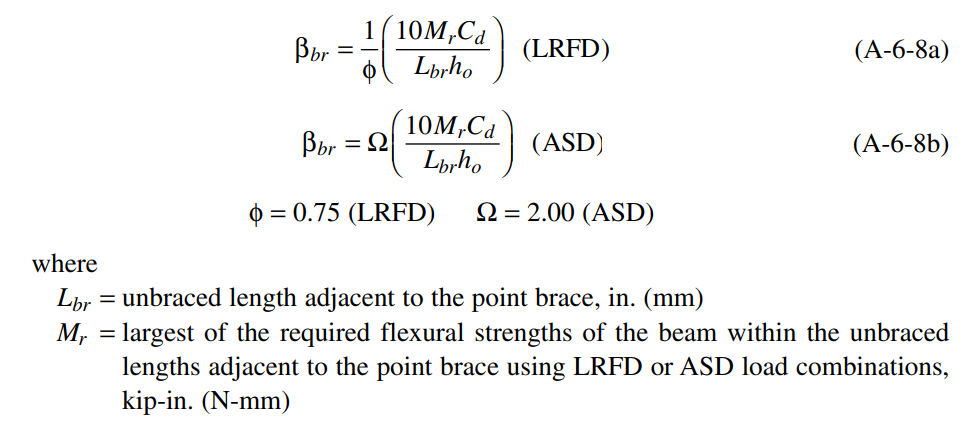

Moreover, βbr is calculated using the following equations.

https://www.aisc.org/globalassets/aisc/publications/standards/a360-16-spec-and-commentary.pdf

It should be noted that:

Moment values are not same in all load combinations, moreover, in non-prismatic sections, section properties (h0) are not identical along a beam. Therefore:

the above-shown equation (A-6-8) should be checked for all load combinations since the values of Mr differ in each load combination. and h0 values should be checked along the element.

Due to this complexity and high computational time in the flange brace design, despite the fact that in warehouses, industrial buildings, etc. flange bracing system is the most economical solution, tie beams are designed and used instead.

MkaPEB, considering the Mr values in all load combinations, and h0 values in along the member, designs the flange bracing according to AISC.

Read more:

BRACING FOR STABILlTY by Yura and Helwig in 1995, available on:

https://www.aisc.org/globalassets/aisc/research-library/bracing-for-stability.pdf

TOWARD IMPROVED FLANGE BRACING REQUIREMENTS FOR METAL BUILDING FRAME SYSTEMS

https://repository.gatech.edu/entities/publication/427b906e-9380-47a8-a7f2-7350a9f14955

Created with the Personal Edition of HelpNDoc: Maximize Your Productivity with a Help Authoring Tool