Lateral torsional buckling in Beams

Another reason exists for significant differences exist in the weight of beams designed by MkaPEB users versus those by a few other engineers. This difference lies in the variation of the method for preventing the Lateral torsional buckling (LTB) in beam.

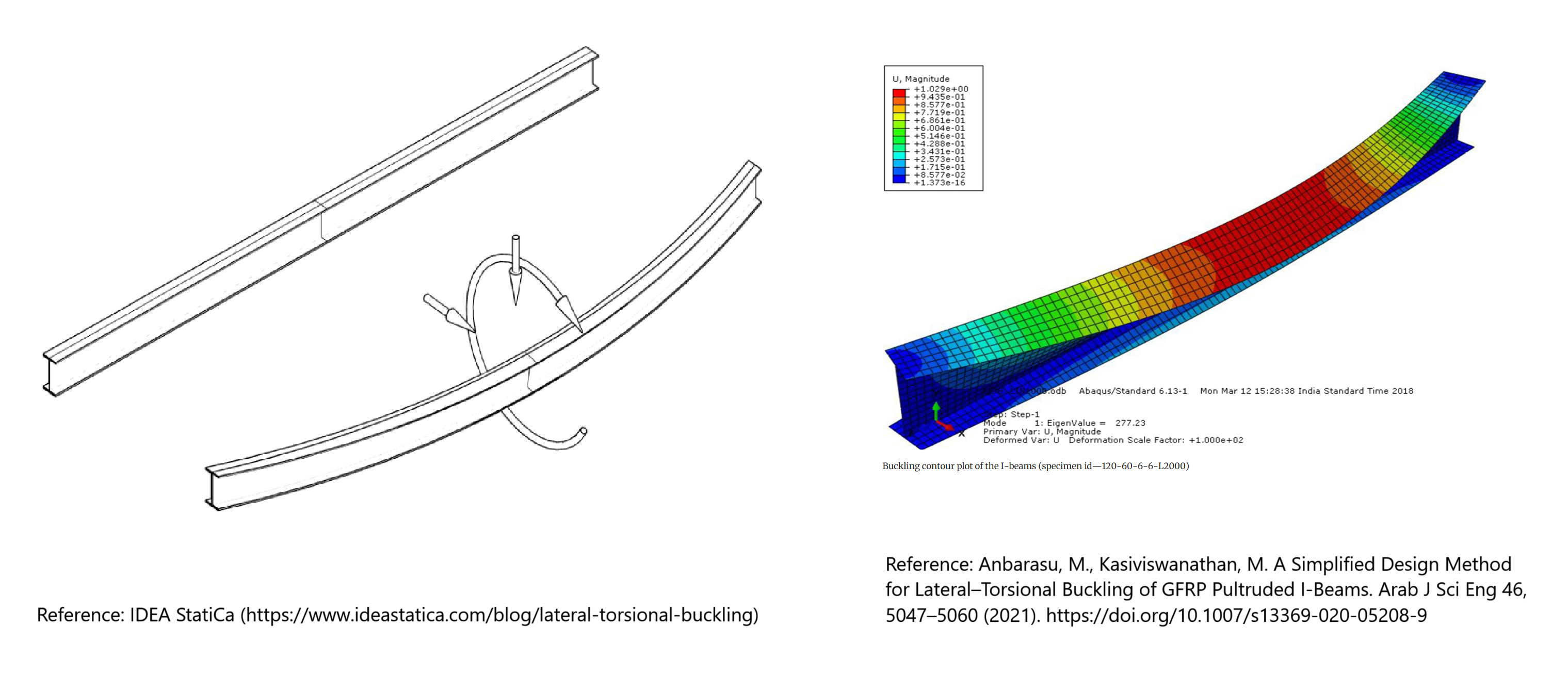

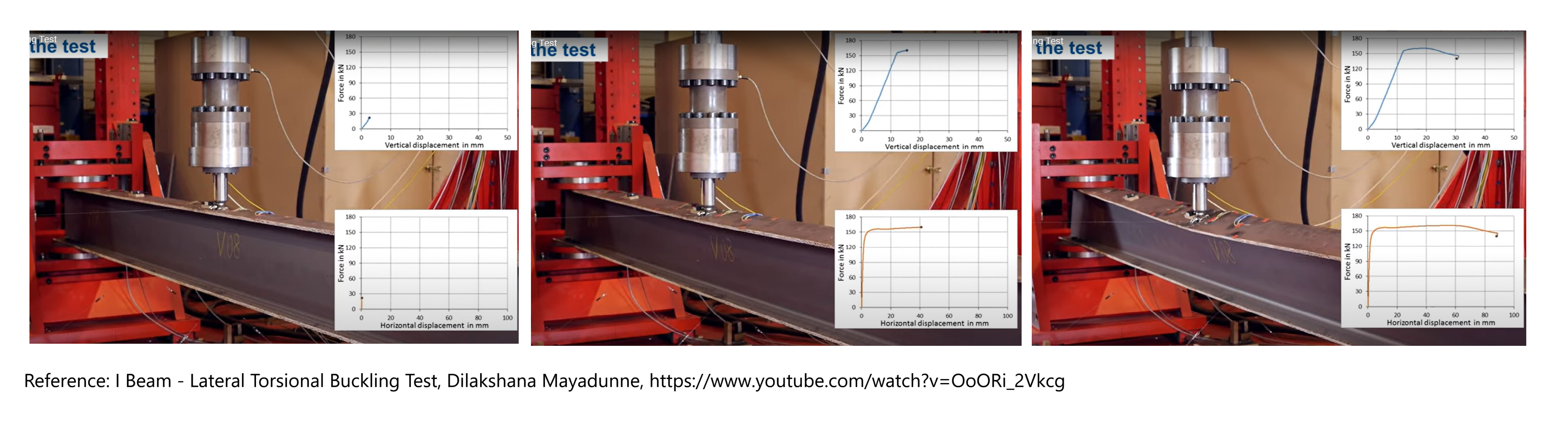

Lateral torsional buckling (LTB) in beam is the deformation of an unrestrained beam due to the applied loads away from its longitudinal axis – both lateral displacement and twisting.

Unrestrained steel beams are beams whose compression flange is free to move (or displace) in the lateral direction and also rotate. If we apply this theory to a simply supported beam then the compression flange is the top flange. As this flange deflects laterally the tension flange tries to keep the beam straight and creates ‘restoring’ forces due to the lateral bending of the beam. However, these forces alone cannot keep the beam straight. The resistance of the beam to LTB is determined by the restoring forces and the lateral component of tensile forces in the tension flange.

https://www.ideastatica.com/blog/lateral-torsional-buckling

https://link.springer.com/article/10.1007/s13369-020-05208-9

https://www.youtube.com/watch?v=OoORi_2Vkcg

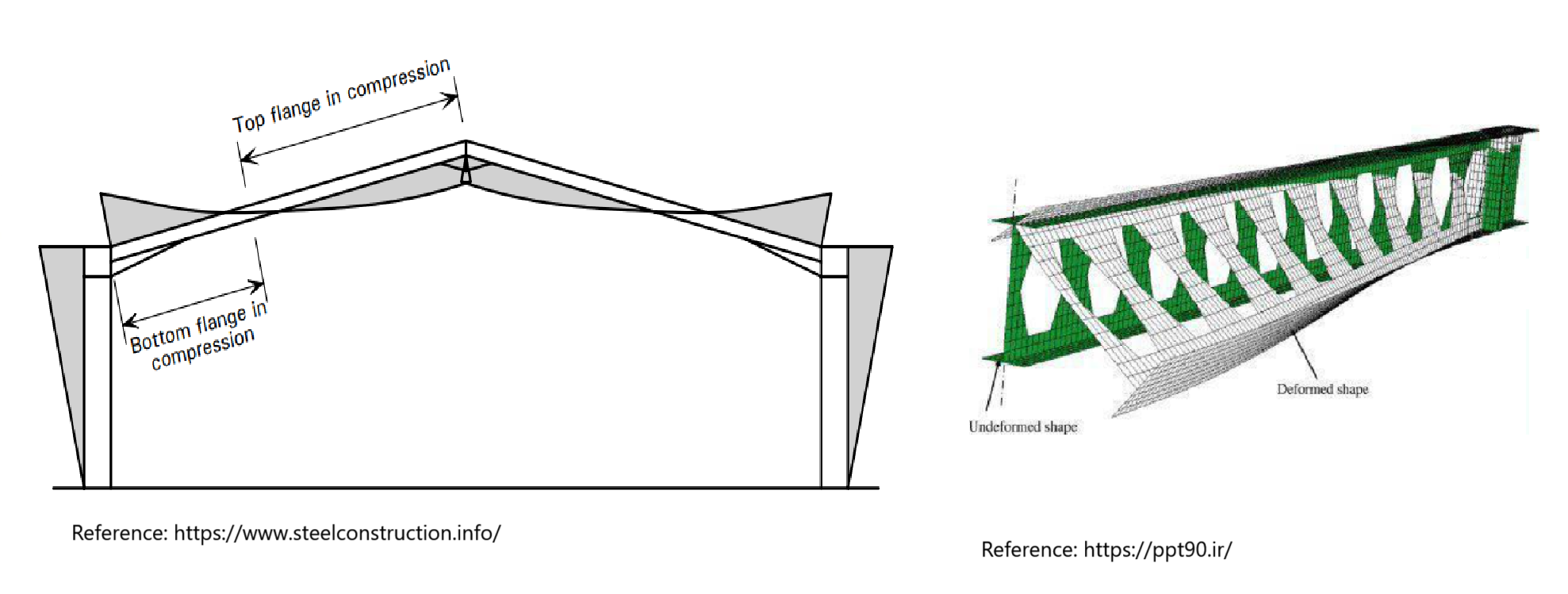

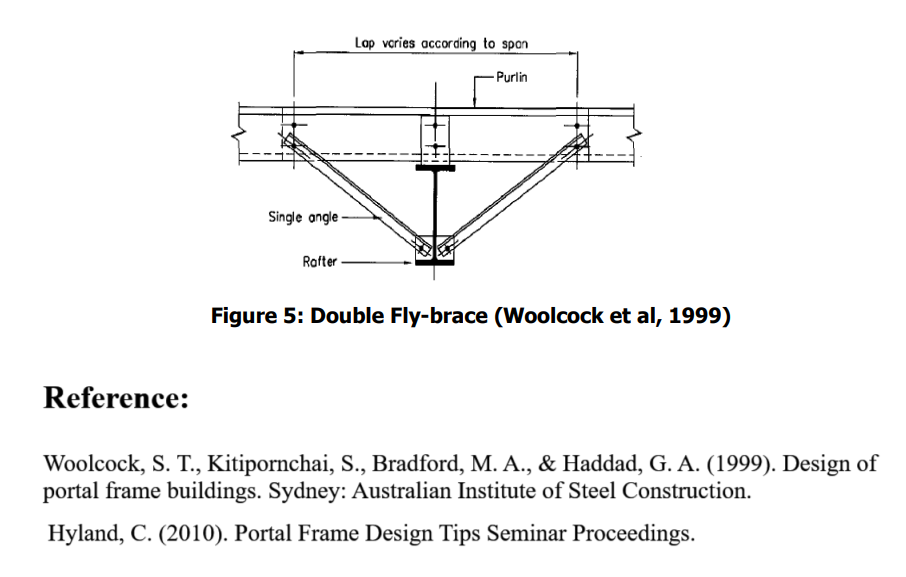

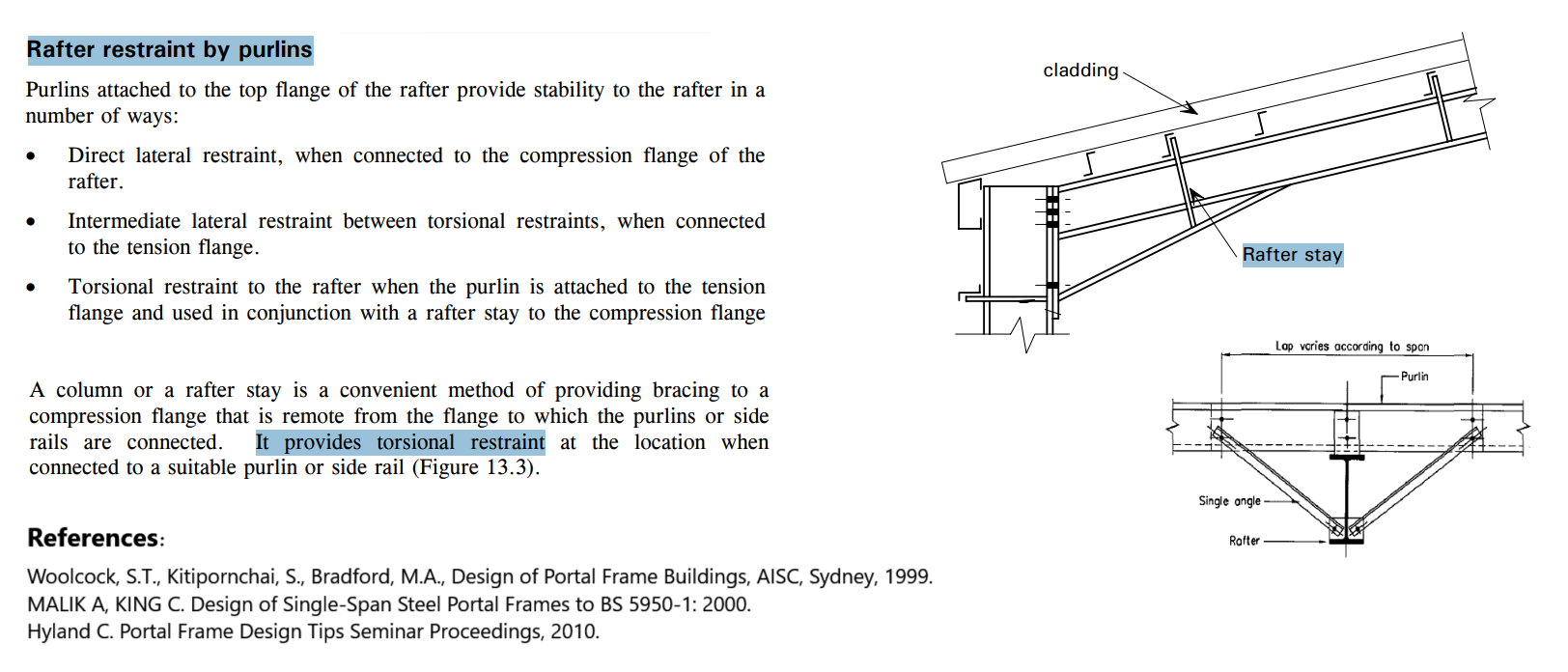

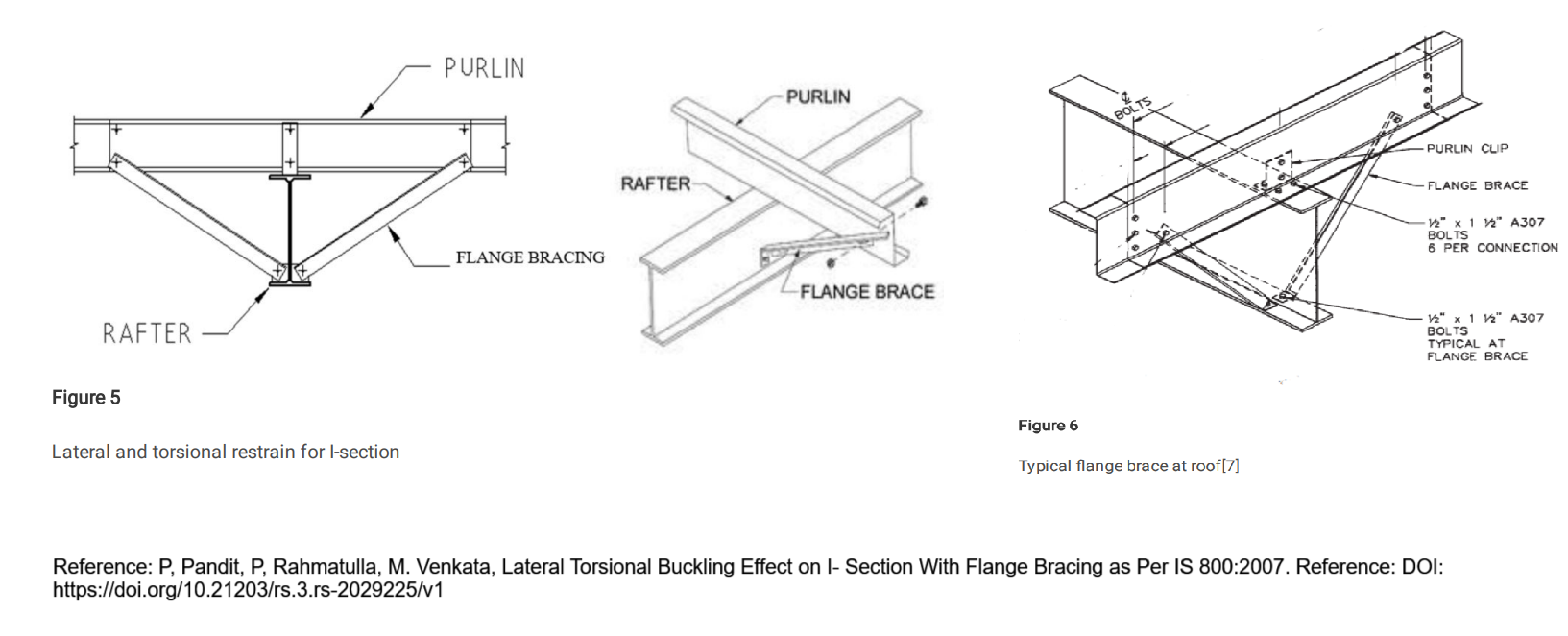

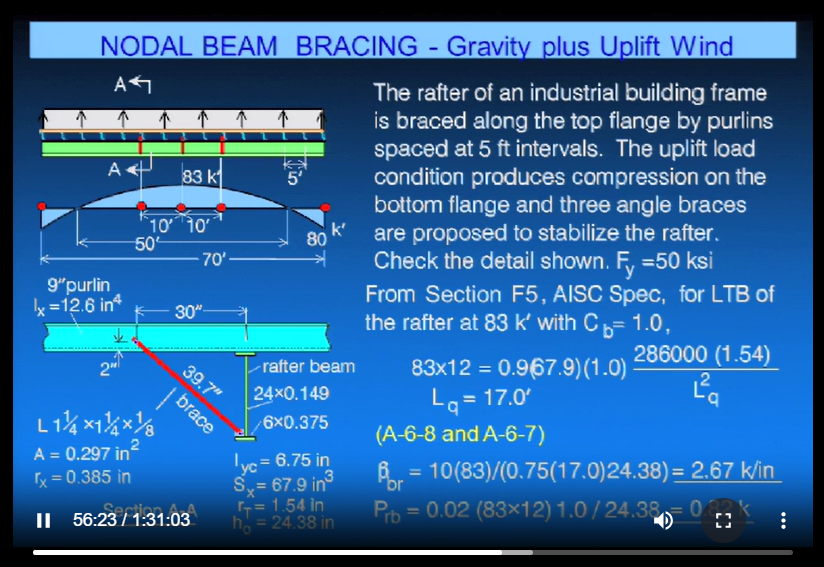

However, in some parts of the rafters, negative moments occur, meaning the bottom flanges act as the compression flanges. In these regions, the bottom flanges must be properly restrained to prevent lateral-torsional buckling.

https://www.steelconstruction.info/images/4/44/SCI_P252.pdf (PDF Pages: 54/171)

https://www.sciencedirect.com/science/article/pii/S0143974X1000283X

It should be noted that the length of the bottom flange acting as the compression flange varies depending on the load combination. Therefore, for each load combination, the unbraced length is calculated separately, and the maximum value among all combinations is taken as the governing (maximum) unbraced length for design purposes.

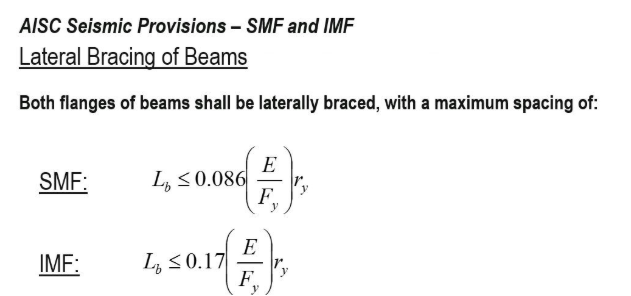

To address this issue, structural codes and standards specify maximum allowable unbraced lengths.

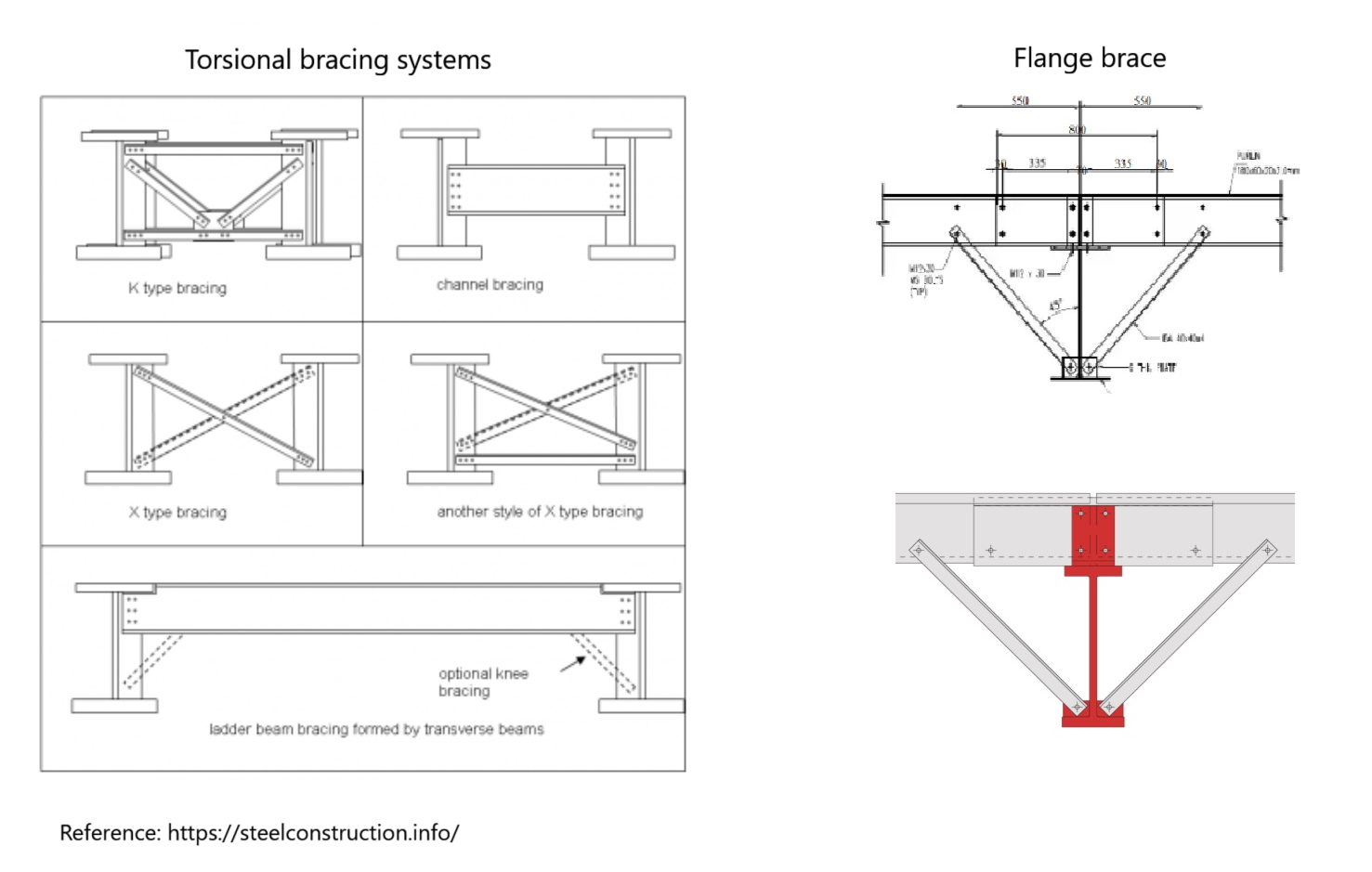

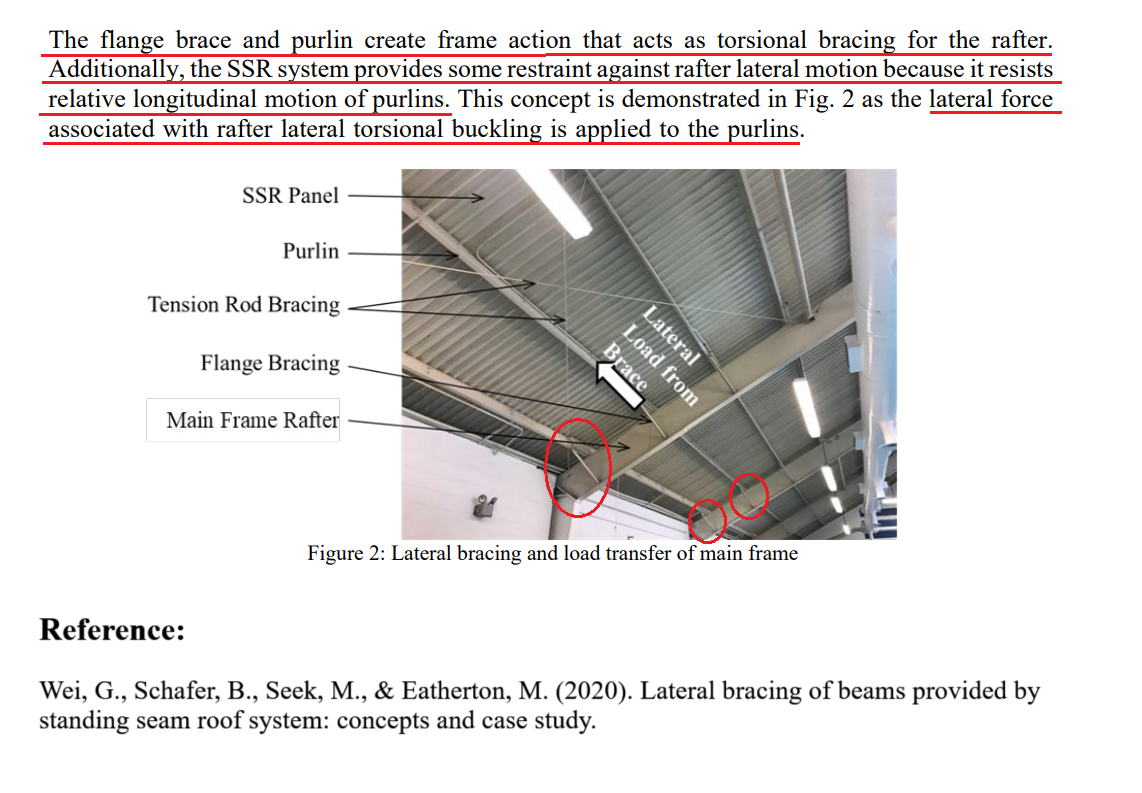

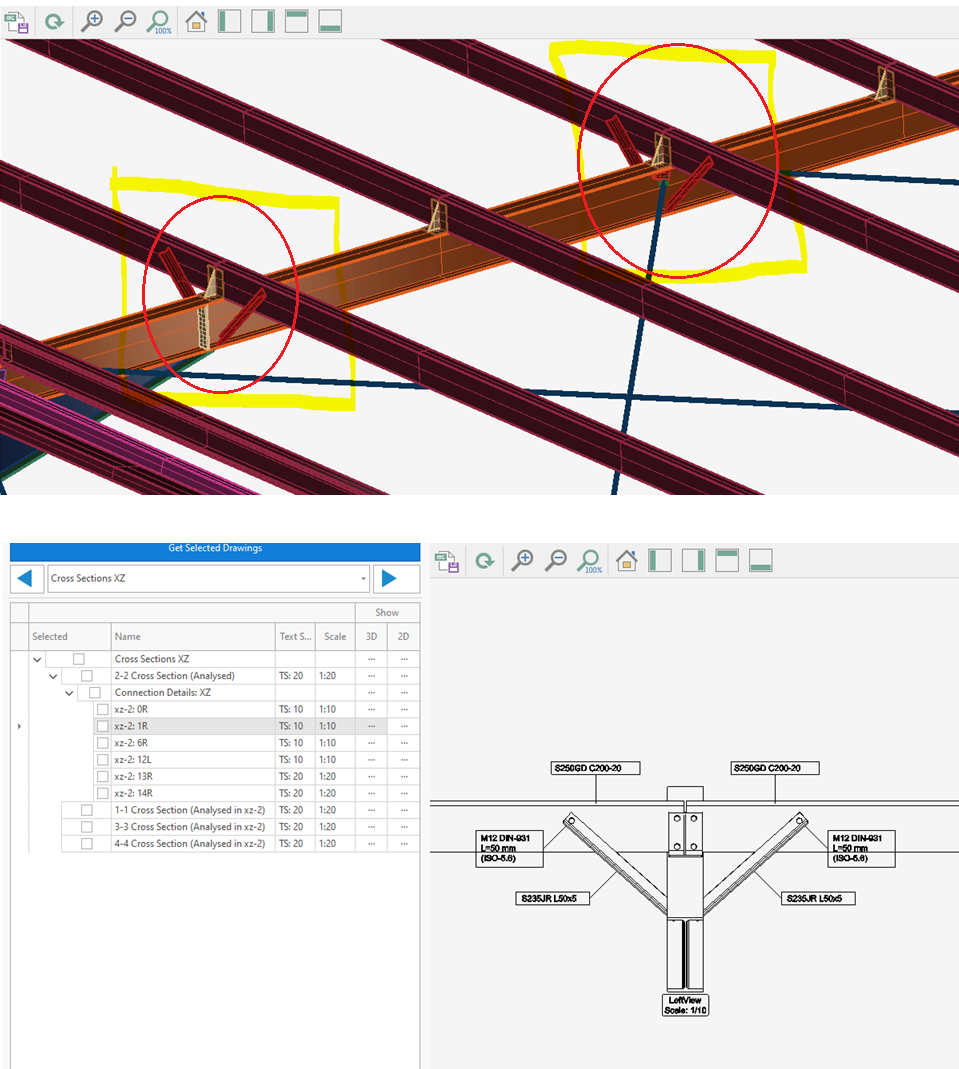

There are several methods commonly used to reduce the unbraced length, such as Torsional Bracing Systems, Tie Beams, Flange Bracing.

https://steelconstruction.info/Bracing_systems

https://www.cmf.uk.com/download/Purlins-Brochure.pdf

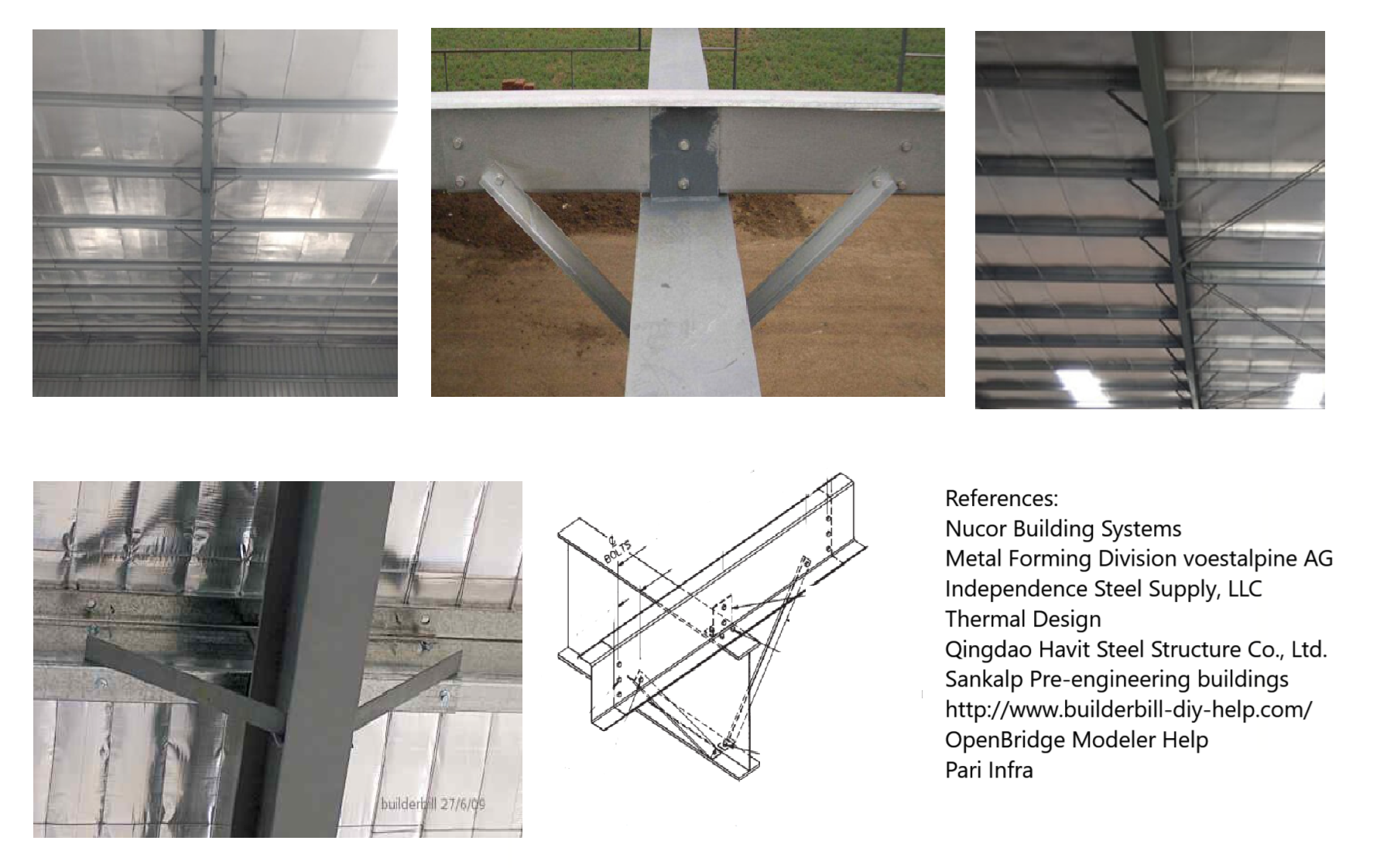

Each bracing method can be considered effective depending on the context, for example for mezzanines, or bridges the torsional bracing systems such as X type bracing are used. However, the same method is used by a few engineers for preventing LTB in beams. While, Flange Bracing stands out as one of the most economical and widely adopted solutions for preventing LTB in the roof of PEBs and Portal Frames. Its effectiveness lies in reducing the unbraced length of rafters without introducing excessive additional weight into the structure, unlike torsional bracing systems. Using this two method for preventing LTB in beams lead to significantly different weight.

It should be noted that the use of flange bracing systems (fly braces or point braces) is neither a novel nor a unique feature of MkaPEB; similar systems have been well documented in references from as early as 1999 and continue to be referenced in current practice.

https://www.scnz.org/wp-content/uploads/2020/12/GEN7001.pdf (PDF Pages: 9-10/21)

https://www.steelconstruction.info/images/4/44/SCI_P252.pdf (PDF Pages:23/171)

https://www.researchgate.net/publication/365200147_Lateral_Torsional_Buckling_Effect_on_I-_Section_With_Flange_Bracing_as_Per_IS_8002007 (PDF Page: 13/16)

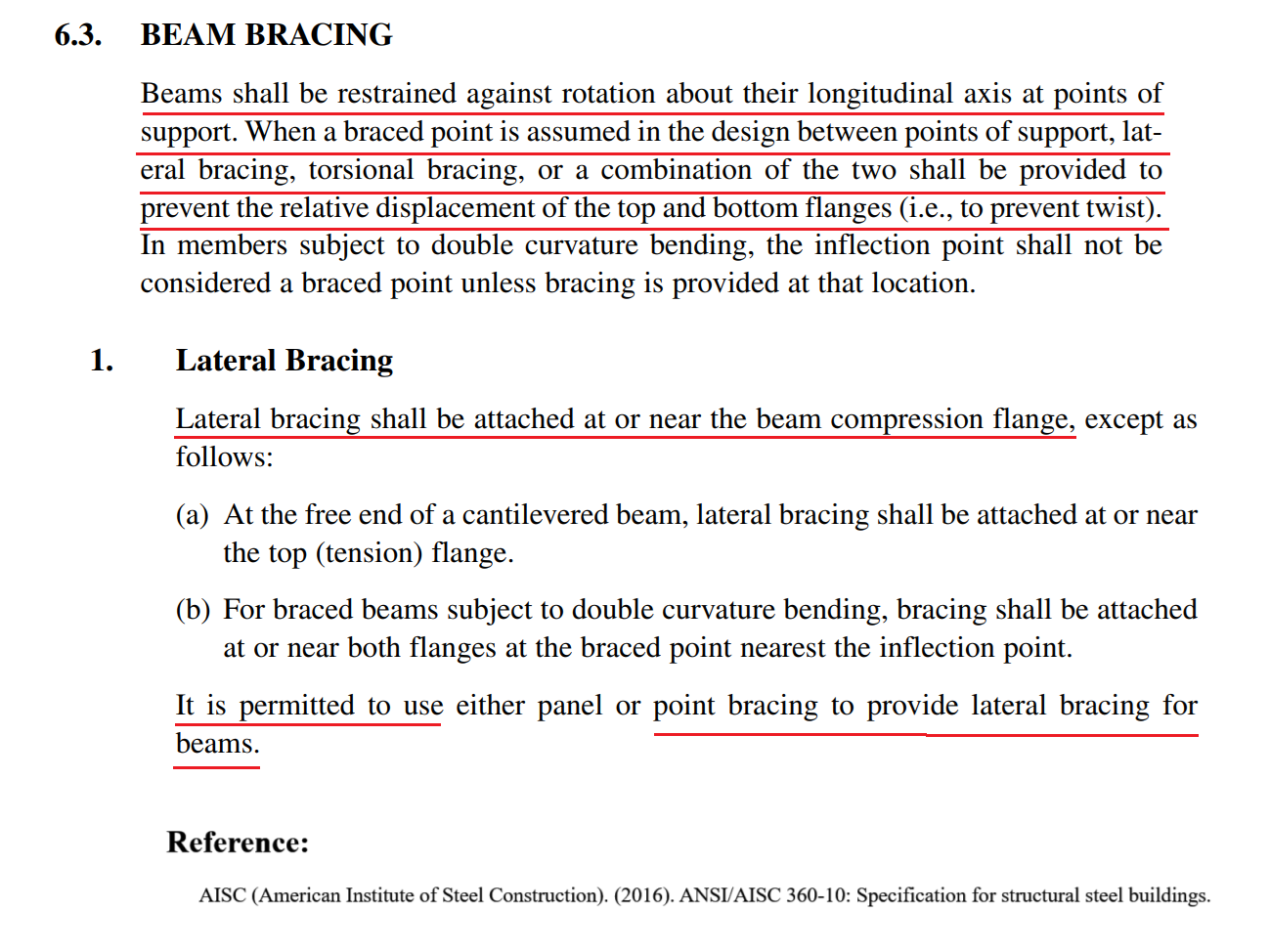

Moreover, this point is mentioned in AISC:

https://www.aisc.org/globalassets/aisc/publications/standards/a360-16-spec-and-commentary.pdf (PDF Page: 296/676)

More details about point (nodal) bracing are presented in AISC.

Thus, this method is used all over the world.

https://www.steelbuildingstructure.com/metal-building/fly-bracing/

http://www.builderbill-diy-help.com/fly-brace.html

https://sunwardsteel.com/steel-buildings/

https://sheerforceeng.com/2021/11/10/what-is-a-fly-brace-and-what-does-a-fly-brace-do/

https://www.youtube.com/watch?v=SX-QWokfsAs

https://www.nucorbuildingsystems.com/wp-content/uploads/2019/02/linerflangebrace12.16.pdf

https://qdsteelbuilding.com/blog/what-is-a-bracing-system-in-the-steel-structure%EF%BF%BC.html

By integrating Flange Bracing into the structural system, MkaPEB provides optimized solutions that are not only safe and code-compliant but also economically superior. This design philosophy allows users to benefit from lighter, more efficient structures without sacrificing performance or reliability.

Created with the Personal Edition of HelpNDoc: Effortlessly Edit and Export Markdown Documents