Strength in Overlapped Parts

In the design of purlins and girts, particularly at support locations where overlaps occur, MkaPEB considers the increase in capacity due to the overlapping sections. In other words, the strength contribution from the two overlapped purlins is summed. This is not a unique consideration — it is explicitly presented in different editions of the AISI Cold-Formed Steel Design Manual.

However, most structural analysis and design software cannot model two sections at the same location and therefore fail to recognize these overlapped regions. As a result, they completely ignore the combined strength in these areas, leading to higher calculated moments at supports. This, in turn, forces designers to select larger, uneconomical, and over-designed sections.

MkaPEB properly accounts for this effect in both the analysis and design of purlins and girts, leading to more economical solutions.

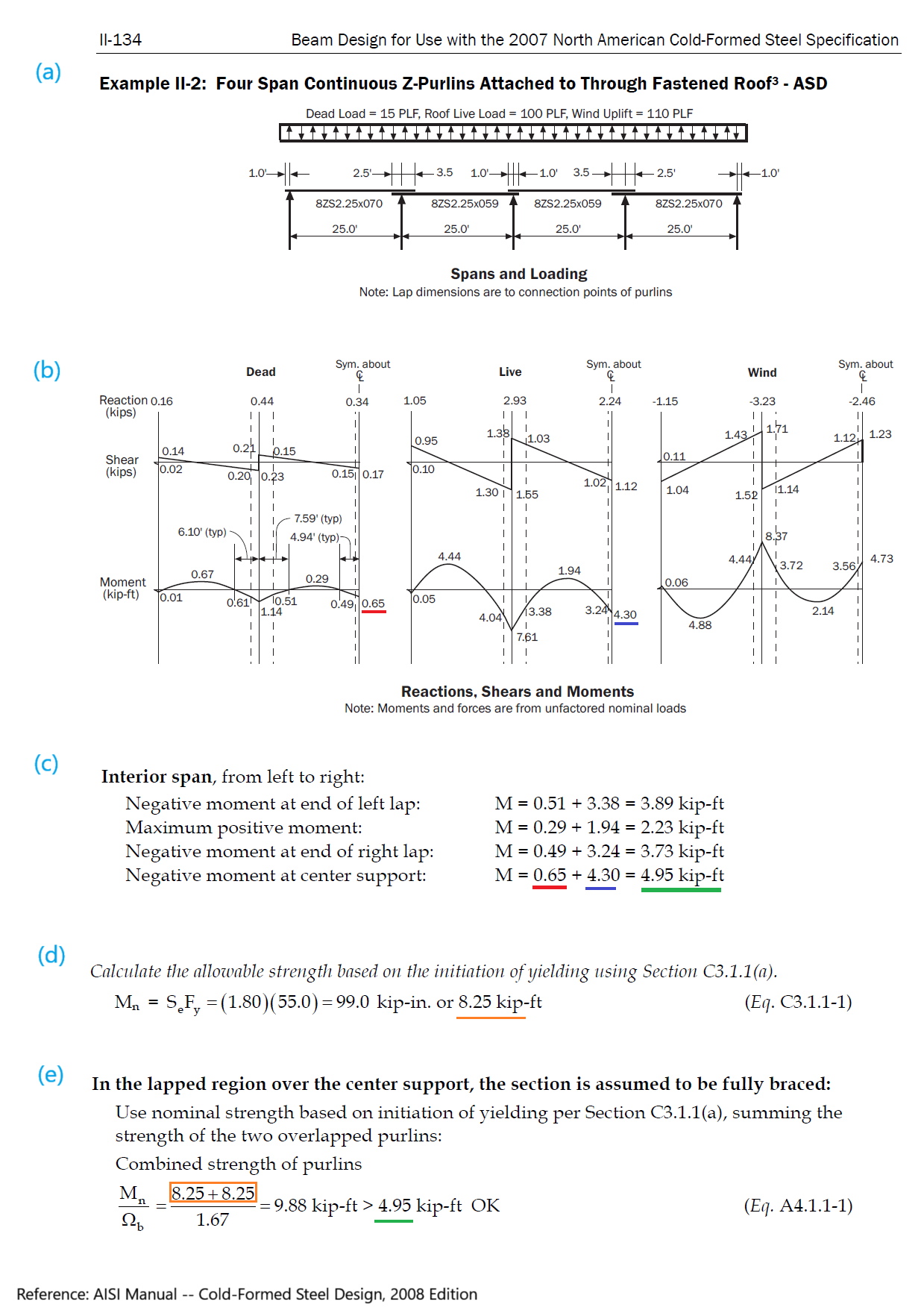

For example, an example from AISI, as shown in Figure (part b), the negative moments at supports are:

0.65 kip-ft (dead load)

4.30 kip-ft (live load)

The total moment is:

0.65 + 4.30 = 4.95 kip-ft (part c)

According to the AISI Manual (Figure part e), the nominal flexural strengths of the two overlapped purlins are summed:

8.25 + 8.25 = 16.50 kip-ft

Dividing by the safety factor 1.67:

16.50 / 1.67 = 9.88 kip-ft

This value is then compared with the total moment:

9.88 / 4.95 = 1.996 (Higher than 1, so it is okay)

MkaPEB applies a similar strategy. MkaPEB divides the negative moment at the support by 2 in the overlapped parts:

0.65 / 2 = 0.325 kip-ft

4.30 / 2 = 2.150 kip-ft

Summing these:

0.325 + 2.150 = 2.475 kip-ft

This is then compared with the strength of a single section:

8.25 / 1.67 = 4.94 kip-ft

This value is then compared with the total moment:

4.94 / 2.745 = 1.996 (Higher than 1, so it is okay)

Thus, the method used by MkaPEB yields the same strength ratio (1.996) as provided in the AISI Manual.

On the other hand,

if the overlap is ignored—as is the case with most other structural analysis and design software—and the design is based on just a single section, then:

8.25 / 1.67 = 4.94 kip-ft < 4.95 kip-ft

Then the section would be considered inadequate, prompting the selection of a larger section.

By correctly accounting for the overlap — by summing the nominal flexural strengths of the two overlapped purlins in the AISI Manual, and by dividing the negative moment at the support by two in MkaPEB — the optimum Z-purlin section can be found.

It should be noted that in MkaPEB, the negative moments at the supports are divided by two only when the overlapped sections are identical. In cases where the overlapping sections differ in size, the negative moments are divided by an appropriate factor, calculated based on the relative sizes (section properties) of the overlapped members.

This same consideration is also applied in the analysis and design of girts in MkaPEB, ensuring consistent and economical solutions.

Created with the Personal Edition of HelpNDoc: Easily create HTML Help documents